Ningbo Sunshine Traffic Equipment Co., Ltd. (hereinafter referred to as Sunshine Wipers) has over 100 employees, including 30 specialists in innovation and R&D. The annual production of soft wipers exceeds 5.5 million sets, with a total value of 120 million yuan. It was the first in its industry to obtain the IATF16949:2020 automotive quality certification. Sunshine Wipers is a large, modern manufacturing enterprise that integrates R&D, production, and sales of wiper systems.

In 2010, Sunshine Wiper established its own brands, BUYLONG and Bai Long Wipers, and entered the Japanese market. After more than ten years, BUYLONG’s share of the Japanese wiper market has reached 3.7%. In our core market of Osaka, BUYLONG’s market share has reached 70%, giving it a near-monopoly position.

Sunshine Wiper’s products are popular in the Americas, Europe, ASEAN, and other regions, providing wiper solutions and services to automakers such as Russia's GAZ and LADA. The company has also established long-term partnerships with renowned companies like Buick, FAW-Volkswagen, GATES, and NAPA. After nearly 20 years of development, Sunshine Wiper has built strong capabilities and a solid reputation in providing complete solutions, manufacturing, and sales of automotive wiper systems, earning the trust of global automakers and consumers.

In 2020, Sunshine Wiper and the Hangzhou branch of the Chinese Academy of Sciences established a laboratory and founded Hangzhou Yingling Intelligent Technology Co., Ltd. Centered on its own brands Bai Long and BUYLONG, the company competed in the domestic market with the goal of becoming the top brand in the domestic wiper category and gradually expanding to cover all categories related to safe driving.

In 2021, it formed partnerships with Beijing Antu, Zhongce Group, ZF's Lucas brand, Zhejiang Huasheng, and other companies.

In 2022, the factory underwent a full upgrade to achieve Industry 4.0. In the same year, the company partnered with Saibang Lubricants and officially launched innovative concepts such as OEM 2.0 and project-based sales of wiper products.

Bekaert steel sheet

The wiper steel sheet is made from Belgium Bekaert plastic steel and manganese steel. It has memory properties, allowing it to rebound two million times without deformation, with a rebound rate 30% higher than other brands.

STP-secondary tempering process

The steel sheet undergoes an exclusive secondary tempering process, enhancing its resilience and stability by 15% compared to before tempering.

EPDM-EPDM rubber

EPDM rubber offers stable weather resistance, with a rebound rate that increases by 70% in extreme cold (-60°C) and a noise reduction of 15%.

CV60- MY SMR CV60 Natural Rubber

The wiper rubber strip is made from selected MY SMR-CV60 natural rubber, combined with a rubber mixing formula developed in collaboration with the Chinese Academy of Sciences. It withstands high temperatures up to 80°C, low temperatures down to -40°C, and is resistant to aging, oxidation, and UV rays. Noise levels are 15% lower than those of other brands.

Si-Water Soluble Coating Technology

The water-soluble coating technology enriches the silicone strip with water-based elements. This reduces the area of white fog during use by 35% compared to traditional coated wipers and decreases fog duration by 47%. The glare while driving at night in the rain is reduced by 32% compared to traditional coated wipers, effectively addressing common glare and white fog issues.

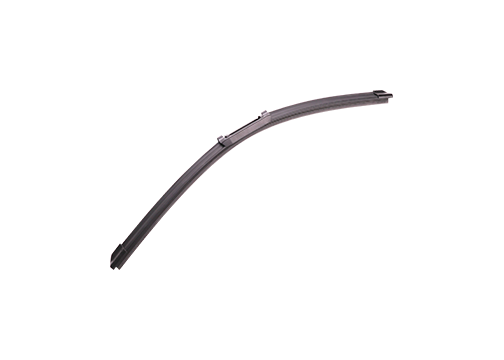

The embedded stainless steel strip provides overall toughness. The rubber strip is soft but does not collapse, resulting in stronger cleaning power.

Our self-developed rubber formula allows the rubber strip to withstand high temperatures up to 80 °C and low temperatures down to -40 °C, while being resistant to aging and UV rays.

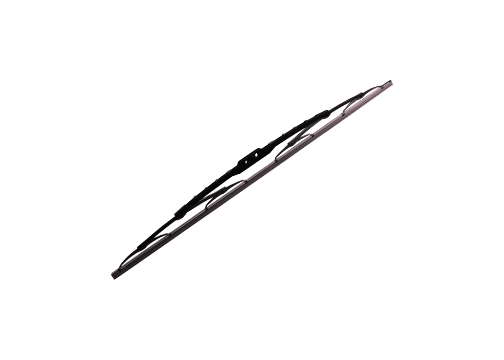

The galvanizing process, combined with electrostatic spraying and a multi-layer coating, ensures a stable finish that does not bubble off. This provides the wipers with all-around corrosion resistance and a long service life.

The full steel strip disperses pressure evenly across all parts.

The deflector’s sloped design, combined with aerodynamics, cleverly uses wind pressure to make the wipers fit the glass better for cleaner rain removal.

The simple structure and elastic steel sheet effectively reduce wiper shaking and wear.

Three-stage structure optimizes the wiper angle and curvature, allowing it to fit the glass more closely.

Streamlined frame reduces wiper weight.

Multi-section protective shell provides multi-directional corrosion resistance.

The protective shell’s sloped design, based on aerodynamic principles, effectively utilizes wind pressure to improve cleaning power, eliminate abnormal noise, and prevent shaking.

1. Project Planning, Product Research & Development and Design

2. Design, manufacture and adjustment of the mold. Quickly open the mold and put it into production, and make feedback optimization in time

3. Imported POM processing and production

4. Malaysian Rubber Curing and Pressing

5. Hot melt molding of rubber strip

6. Rubber strip aging treatment and spraying drying and other processes

7. Adhesive strip segmentation

8. Beam/Metal wiper blades electrostatic spraying treatment

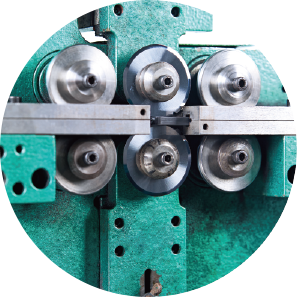

9. Pure imported BEKAERT steel bar pressed boneless steel sheet

10. Deep numerical control steel sheet machine

11. Tempering process treatment

12. Assembly of wiper main parts and spare parts

13. Wiper Assembly & Packaging